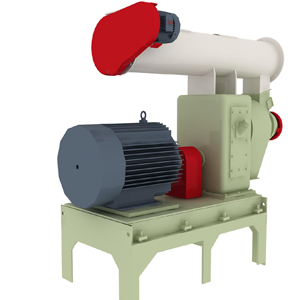

Fish also need to be fed using the right kind of feed. Even though there are different kinds of fish, they more or less, eat the same types of feed. The fish feed pelleting machine is designed to produce the right kind of feed. This type of machine is great in helping to feed fish both domestically as well as commercially. You can produce feed for your fish, or for the purpose of selling to people who own fish at a fee. If you own a fish farm, you definitely need this machine to make your work much easier. It provides fish farmers with an inexpensive way to ensure that their animals are adequately fed.

Get a vegetable medley and puree it together. Afterwards, look for some protein and add it into the mixture. A few examples of protein sources you can get and use for this purpose include fish meal, as well as sea food medley. It could be frozen, dried or fresh. Blend the whole mixture until it is very soft before you add a few vitamin sources. Some of these vitamins include fish oil tablets, algae supplements, and semolina. Use potato ricer, or meat grinder, or pasta maker to run the mixture until noodles form. Use a knife to cut these noodles into smaller pellets.

Once the pellets are cooled, place them in an oven after covering them with a foil or dry sheet. However, you should ensure that the heat is kept low while drying the pellets to feed your fish. You can also use a dehydrator in the place of an oven. While you are still cooking the pellets, you can scatter some oil on them. You should store the pellets inside freezer bags, and once this is done, the pellets can stay fresh for a period of not less than six months.

The last step is to let the pellets cool down in a cooler so that they are ready for use as fuel. However, it is important to use only those that are hardened well after the production process.

The last step is to let the pellets cool down in a cooler so that they are ready for use as fuel. However, it is important to use only those that are hardened well after the production process.